In the realm of scientific research, sample integrity is paramount. From biological samples to chemical reagents, preserving their quality over extended periods is crucial for accurate and reliable results. One of the most effective methods to ensure sample integrity is through the use of a semi-automated well plate sealer.

The Importance of Proper Sealing

Improper sealing of microplates can lead to several issues, including:

Evaporation: Volatile compounds can evaporate over time, altering sample concentration and compromising experimental outcomes.

Contamination: Unsealed wells are susceptible to contamination from airborne particles, dust, and other contaminants, leading to inaccurate results and potentially compromising the entire experiment.

Cross-contamination: Samples can cross-contaminate each other if not properly sealed, especially when stored for extended periods.

The Role of a Semi-Automated Plate Sealer

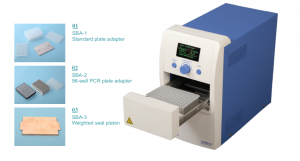

A semi-automated plate sealer offers a precise and efficient solution to these challenges. These devices apply a secure seal to each well of a microplate, creating a barrier that prevents evaporation, contamination, and cross-contamination.

Key benefits of using a semi-automated plate sealer:

Enhanced sample integrity: By creating a hermetic seal, plate sealers ensure that samples remain stable and unaltered over time.

Improved reproducibility: Consistent sealing across all wells improves the reproducibility of experiments.

Time efficiency: Automated or semi-automated sealing is significantly faster than manual methods, increasing laboratory productivity.

Versatility: Most plate sealers can accommodate a variety of plate formats and sealing films, making them adaptable to different laboratory workflows.

Reduced risk of injury: Automated sealing reduces the risk of repetitive strain injuries associated with manual sealing.

Key Features to Look for in a Plate Sealer

Sealing film compatibility: Ensure the sealer can accommodate the specific type of sealing film you use.

Plate format compatibility: Check if the sealer can handle various plate formats, such as 96-well, 384-well, or deep-well plates.

Sealing force: The sealing force should be adjustable to accommodate different sample types and sealing films.

Speed: A faster sealing speed can increase laboratory throughput.

Ease of use: A user-friendly interface and intuitive controls make the sealer easier to operate.

Applications of Plate Sealers

Plate sealers find widespread applications in various scientific disciplines, including:

Molecular biology: Protecting DNA, RNA, and protein samples during storage and transportation.

Clinical diagnostics: Securing samples for diagnostic testing and analysis.

Drug discovery: Preserving compounds and reagents for screening and assay development.

Food and environmental testing: Protecting samples during analysis and storage.

A semi-automated plate sealer is an essential tool for any laboratory that requires long-term sample storage. By preventing evaporation, contamination, and cross-contamination, plate sealers ensure the integrity of valuable samples and contribute to the success of scientific research. Want to learn more, you can visit: www.ace-biomedical.com

Post time: Dec-23-2024